Finished products parameters

1. Coil inner diameter: φ508 mm

2. Coil external diameter: φ1500mm:

3. Material Weight: The maximum coil weight 15 tons * According to customers’ specific requirements

Equipment components:

1. Hydraulic uncoiler 1 group

2. Support arm 1 units

3. Loading and unloading car 2 sets

4. Winding machine 1 group

5. Hydraulic system 1 set

6. Electric control system 2 sets

Equipment components Description:

1.Hydraulic uncoiler

The hydraulic uncoiler is driven by the hydraulic cylinder to move along the guide rail; expanding-collapsing supporting canister by the hydraulic cylinder with rotary joints for expanding-collapsing , Motor through the reducer,Gear-driven support tube rotation, A clutch is provided in the transmission system of the support drum rotation,the uncoiler provides the main force for galvanized coil heads. Uncoiling with two types active and passive , when the active uncoiling motor-driven assist feeding; Passive uncoiling, the clutch in the transmission system disengaged, the brake work to prevent galvanized roll inertia rotation, independent electronic control operation.

Uncoiling press roll base fixed on the ground foundation, uncoiling press roll driven by hydraulic cylinders, adjustable clamping force.

Body is made of steel plate welded box, bearing pedestal, the body carrying a maximum weight of 30 tons;

Hydraulic lifting arm,Motor reversing, Pneumatic brake and other functions;

Coiling block expanding-collapsing range: Φ460 - 520mm;

Spindle: 40Cr solid round steel by rough turning, quenching and tempering, finishing turning and other processes ;

Coiling drum composed by Four block arc-shaped plate, cylinder push-pull generated expanding-collapsing ,Rotating cylinder rotates together with the spindle;

Coil drum rotation by the motor supporting reducer; the use of chain drive or main motor direct way to connect;

Pneumatic brake: for coil drum to automatic rotation, to avoid the coil material anti-loose;

Arc-shaped plate plating hard chromium on the surface.

2.Loading and unloading vehicles:

The trolley has a walking and lifting function, walking by the cycloid motor or hydraulic cylinder drive to complete the material action. The coil lift is driven by the hydraulic cylinder. Trolley position controlled by travel switch (motor drive mode),and with uncoiler machine to form a chain protection. To ensure function that the trolley smooth discharging and unloading uncoiling sleeve .

Structure: steel plate welded, after finishing , composed by the activity base and V-shaped units, four guided column type;

Cylinder lifting V-shaped platform lift, four guide column design, lifting height of 500mm;

Discharging way : Longitudinal type

3.Coiling machine :

Accept with mandrel type coiling structure. Steel plate welded divided type gear box, after stress annealing to the whole finishing, having the oil and oil temperature display function (Optional).Motor and reducer coupling directly, Spindle with 40Cr by rough turning, quenching and tempering, finishing turning and other processes ; Pneumatic brakes (optional) ,with Linear guides lightweight, flexible (optional), using hydraulic automatic correction system (optional) and tension frequency conversion or DC converter speed control, to ensure the uniformity of the receiving material,winding mandrel supplied by the customer or a separate optional accessories, can be independent of electronic control, can also be linked with the rolling mill (constant speed, constant torque).

4.Hydraulic System (1 set)

The main structure: tank by the steel welding tank, the capacity of 300 liters and all kinds of hydraulic valve.

Power: E-grade, 5.5KW motor, direct vane pump (Taiwan). Maximum pressure 10MPa, the normal pressure 7MPa.

5.Electric control system (2 sets)

Main power: 380V, 50HZ, 3-phase 5-wire system.

The main electrical components:, leakage protection switch, AC contactors, fuses, thermal breakers and so on.

Various types of switches, electric control valves, electrical lines etc.

All line using variable frequency constant tension control, hydraulic automatic correction system.

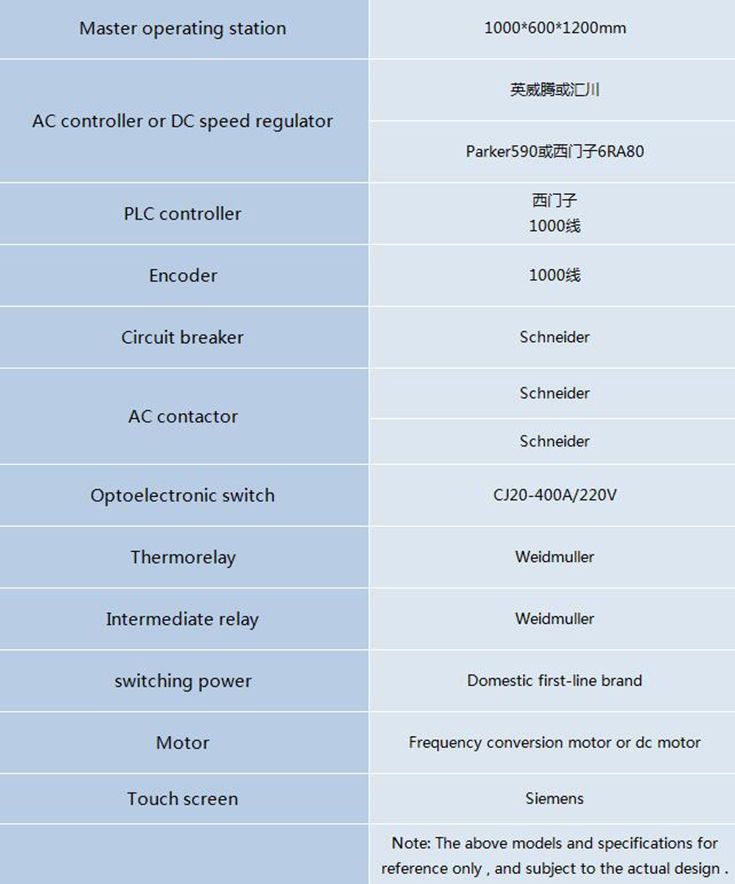

6.Electrical accessories table and brand